Ron Stultz

"How to Replace the Run Capacitor in the Compressor Unit"

Summary: the run capacitor, located in the outside compressor unit, is the most common failure component in HVAC. Replacement can be a do-it-yourself (DIY), if you are careful.

Run capacitor replace?

Never replace parts unless you are sure or think you are sure they are bad or defective.

Before replacing the run capacitor, make sure you read, HVAC - Outside Compressor and Fan Not Starting or Running.

Warning:

HVAC has 240, death, alternating current (AC) voltage.

Do not attempt any do-it-yourself (DIY) repairs on HVAC if you have never worked with or around high voltage.

Always, double and triple check that circuits are dead. This means using a voltmeter.

Do not trust a circuit breaker.

Do not trust a quick disconnect.

Do not work on HVAC when you are tired or too hot or pressured.

Yes, it can get hot inside without HVAC but better to suffer through a hot house and get whacked by high voltage.

Alert:

HVAC replacement parts are available from multiple sources on the Internet, no questions asked, but most HVAC repair companies will not sell parts directly to a homeowner (liability and they want to service your unit).

I am lucky in that I live near an electric motor rebuild shop that carries HVAC motors and run capacitors they will sell to anyone.

So, if you are thinking about DIY HVAC repairs make sure you have a source for parts. You might have no choice but to pay someone to repair your unit.

Run capacitor costs? From Internet sites, about $8 a piece. From electric motor repair shop: $20. Repairman will charge you $30 or more.

Tools:

Flat blade screw driver.

Perhaps nut driver or pliers.

Voltmeter that can read 240 volts alternating current (AC).

Insulated pliers.

How to remove a defective run capacitor:

In your home circuit breaker box, you most likely have 2 circuit breakers related to your HVAC: one for the inside blower and one for the outside compressor unit.

Locate both circuit breakers and move them to the "off" position.

Move to the outside compressor unit.

At the quick disconnect, either toggle the switch to the "off" position or remove the insert by pulling outward.

.jpg)

Find and remove the access panel on the compressor unit.

When working around the outside compressor unit, be careful to not step on the pipes coming out of the unit.

.jpg)

jpg.jpg)

Using your voltmeter set to a scale that will read 240VAC, place your probes on the 2 largest wires at the bottom of the relay and confirm there is no voltage present.

If you read any voltage at all, do not proceed. Believe it or not, I have seen circuits tied directly to power company house mains!!

Remove the screw holding the run capacitor strap in place and holding the run capacitor lower it down and then upside down, with all wires attached.

Do not touch the terminals of the run capacitor with your fingers. Capacitors store charge and although a whack from a capacitor will not kill you, it might startle you enough, you fall or otherwise hurt yourself.

Now look closely at the terminals end of the capacitor.

.jpg)

.jpg)

Raised up out of the metal should be: COM, Herm and Fan.

Take a piece of paper and write down the color of wires going to each terminal.

Double check your notes and compare to the wiring diagram on the back of the access panel.

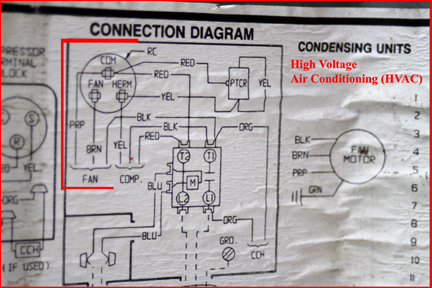

On my diagram below, the run capacitor is on the left and marked "RC".

When you are sure you know absolutely which wire goes to which run capacitor terminal, take an insulated screwdriver and short across the COM terminal and either of the other 2 terminals and then short the other terminal to COM.

Using insulated pliers carefully pull all wires off the run capacitor terminals. Pull at the push-on connector, not just the wire.

Once you have the run capacitor out of the compressor unit, being careful of the terminals, rotate the run capacitor until you can see its label.

.jpg)

This label will define what you must buy as a run capacitor replacement.

How to install a new run capacitor:

Once you have a new run capacitor, mark the outside of the capacitor with a marker of some kind such that you know the definition of each terminal: herm, com and fan.

Although marked on the bottom in the metal, it can be difficult to consult the bottom once you start connecting wires to terminals.

Using your pliers, push the connector of each wire over a terminal on the the run capacitor.

Double check that the right color wire is on the correct capacitor terminals.

Triple check that the right color wire is on the correct capacitor terminal.

Mount capacitor back into compressor unit.

Note that run capacitors vary in diameter and you might have to shim the capacitor to get the retaining strap to hold it tight against the unit wall.

With the run capacitor mounted, double check that all wires are attached to a terminal and there is no loose wire ends anywhere.

Take a break and move away from the compressor unit.

Come back to compressor unit and check everything over again.

Place access panel back on compressor unit and tighten screws.

Toggle the quick disconnect to "on" or insert the fuse\metal block back into the quick disconnect.

Turn on circuit breakers to air handler and outside compressor unit.

If a breaker immediately trips, you have a wiring problem and immediately place both breakers in the "off" position and go take a break before looking at compressor wiring again.

Go to a thermostat connected to the unit being worked on and set to "cool" and a temperature below current room temperature.

The fan motor on top of the compressor unit should start turning immediately, if it is not defective.

The compressor unit may try to start and then shut down. Do not worry.

Wait.

The compressor unit will try to start again after a short time.

The compressor unit may try to start several times before it starts and continues to run.

If the fan motor makes a loud humming noise and does not turn, it is defective and must be replaced.

If the compressor unit does not eventually start and continue to run, best to call a HVAC repairman.