Ron Stultz

"Hydronic Heating System - Installing Circulator Pump"

Summary: highly likely that you will have to loosen and rotate motor to get correct water flow.

Background:

Switched on my hydronic heating system just confirm it ready for fall and winter.

Circulator pump did not want to pump. Was "running/humming", getting hot, but no water flow.

Ordered a new pump.

Installation:

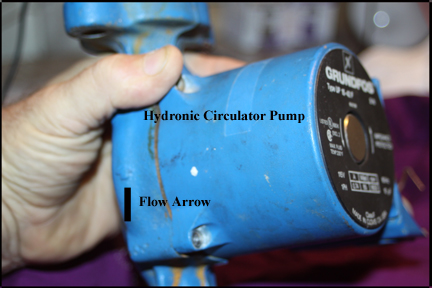

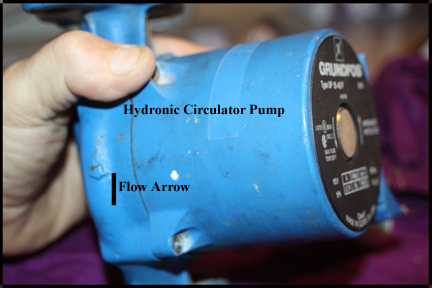

When new pump came, it looked like below. Could easily read end of pump and arrow on pump mating flange was pointed up.

But, in my system, the water flow is down at the flange, SO, had to loosen motor (5/32 Allan wrench) and rotate flange until flow arrow was pointing down.

FYI: the mating flange is chambered and thus must be in correct direction for pump to work.

Electrical:

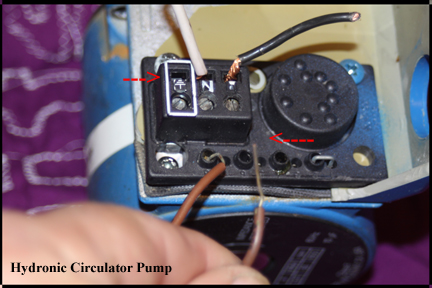

On my system the motor is connected to the Honeywell controller via flexible metal conduit.

When I removed the cover over the pump electrical box, found a black and white wire but no ground wire!

Understand that controller has electrical ground connected to box and flexible metal conduit carries ground but electrical box on pump is plastic and thus no ground connection via conduit!

Ok, so whole pipe system is a ground, right? Don't care. Run a ground wire from controller to motor.

ALSO, note that there was a starter capacitor inside the electrical box and that the wires of the capacitor were simply pushed down into connectors. BUT, one wire was so loose in connector not sure it was making any sort of contact at all. Problem with pump not starting??????

Mating Flange:

OK, so mount motor so flow direction is correct, wire it up and fill system.

New pump starts up and no leaks and let it run for a while getting air out via whole house air scoop.

Couple of hours later, see water seeping around threads on upper system pipe flange. This is cast iron flange that is screwed into male cooper 1 1/4 inch. What???

Take out flange and using Teflon tape wrap threads on cooper male threads and reattach metal flange.

Again, allow system to fill with water.

And again, water seeping at same flange!!!

SO, take out cast iron flange again and this time examine threads on flange and find one thread has sections broken out of it!!!

SO, buy new flange and flexible pipe sealant.

Use sealant on threads of male cooper and inside threads of cast iron flange and re-couple.

This time no seep!!!

SO, bottom line is you have a water seep, check threads and use special pipe sealant and not Teflon tape.