Ron Stultz

"Hydronic Heating System - Water Pressure Regulation Components"

Overview:

Maintaining the correct hydronic heating system water pressure is critical to correct system operation:

- Water pressure that is too low can result in gurgling noises as water moves through piping or poor heating on floors significantly above the location of the furnace, such as on the 3rd floor of a 3 story home.

- Water pressure that is too high can result in the pressure relief valve venting water on the floor near the furnace and in a worse case, splattering a home owner with very hot water.

Components of water pressure regulation:

There are 4 system components involved in hydronic heating system pressure regulation:

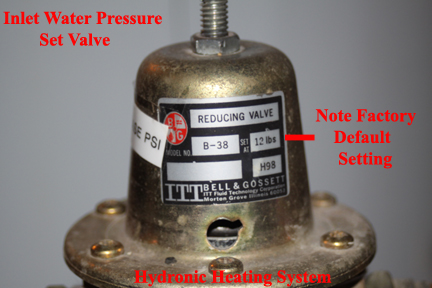

- Inlet water pressure valve.

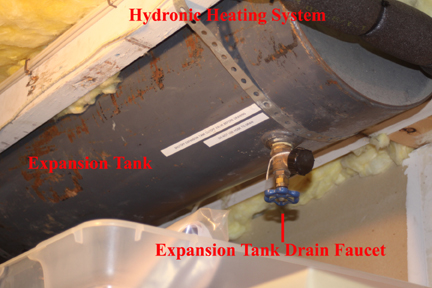

- Expansion tank.

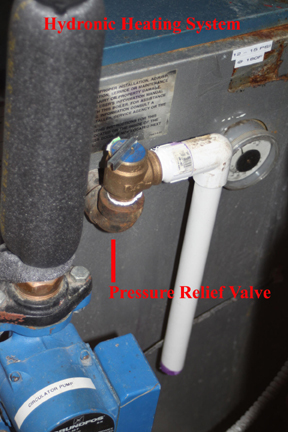

- Pressure relief valve.

- Drain faucet below circulator pump.

Inlet water pressure valve. The inlet water pressure valve is the component that most directly defines hydronic heating system water pressure. Water is fed (initially filled and any water drained from the system replaced) the piping of the heating system through this valve. If the valve is set to 12 pounds per square inch (PSI), house water will flow into the pipes of the hydronic heating system until the system has a pressure of 12 PSI.

Expansion Tank. As water is heated it begins to expand. If the container heating water is in is full of water and closed, water pressure will rise. To "absorb" the increase of water pressure do to heating, hydronic heating systems have an expansion tank An expansion tank works because (1) air compresses more easily than water and (2) although closed, the expansion tank is not full of water. As water fills the tank initially, it compresses air in the tank until the air pressure is equal to the water pressure. Then when water in the hydronic system heats up and expands, heated water in the tank compresses the air in the tank some more.

Pressure Relief Valve. A hydronic heating system has an automatic pressure relief valve on the output side of the furnace. This safety device is there to prevent water pressure in the system from getting so high a pipe could rupture or water could cause some pipe junction to fail. In my case, this automatic valve opens when the water pressure gets at 35 pounds per square inch (PSI). If you look at your valve, it will say somewhere on it about the pressure at which it will release water. The value defined on the pressure relief valve is obviously the upper limit a hydronic heating system can safely operate below. So, if the default inlet water pressure valve has a value of 12PSI and the pressure relief valve is set for 35PSI, any heated water pressure in between is legal.

Drain Faucet Below the Circulator Pump. If water pressure is below the pressure relief valve set pressure but is too high for any reason, the drain faucet below the circulator pump is the place to drain off pressure. Because this faucet sits just below the pump and before the furnace, water drawn from here comes from all zones and loops. Please note, that it does no good to drain pressure if the cause of the high pressure is not corrected first. Causes of high system pressure are (1) inlet water pressure valve set for too high a pressure or expansion tank completely full of water.