Ron Stultz

"Sears DYS4500 Lawn Tractor - Suggested Modifications"

Summary: Easy enough modifications that make the Sears DYS4500 better.

Gasoline fuel line shutoff valve.

Read any small gasoline engine manual and they all tell you to drain gasoline from the carburetor (carb) before storing the unit for the winter or other extended periods of time. The manual suggested method to do this is to run the engine dry of gasoline. Yeah, right. And we are all going to perfectly time our gasoline usage so we run out just before winter storage. Drain the carb bowl of gasoline? Install a fuel line cutoff valve. Now, park the tractor, turn the fuel line valve to closed and let tractor run into carb bowl is empty. Oh, and do not leave key in "on" position after fuel starvation or battery will run down and hour meter will record all key time and not run time.

Information Labels. Probably an obsession or fetish or something but I create and stick information labels on just about everything. Just seems to me to make sense to dig out certain information once and then put it right where it is needed, time after time. For example, I created a label showing oil weight and amount and posted to top of engine. Created and posted right beside engine runtime meter, information on when to change oil and filter "50, 100, 150, 200, 250, 300." I also create and post tire pressure (TP) right on the frame above the applicable tire. Like I said some sort of obsession but saves me time from having to look up the same information over and over and over again.

Replacement of oil drain plug:

Never much liked oil drain plug arrangement. (1) Leaks oil around where plug goes into oil sump; (2) leaks oil around plastic valve even in closed position and (3) valve so short when pulled out to drain, oil drips down side of frame and thus hard to catch in oil pan.

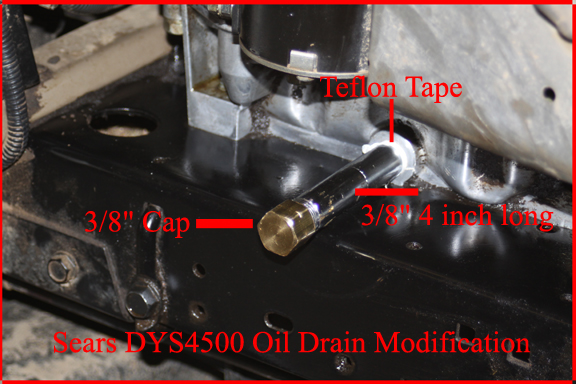

In summary, what I have done is remove old drain plug and replace with a 3/8", 4 inch pipe and cap. I used Teflon tape on the pipe threads that go into the oil sump on the engine and a pipe wrench to get the pipe good and tight. I used a chrome piece of pipe as quickly found at Home Depot but any 3/8" 4" long pipe would have worked. Oh, thought about 6inch long and that would have worked as well.

To remove the stock oil drain plug, you have to pull the plasticc valve off the metal of the drain plug. Found there was no way to get either a socket or wrench on large head of drain plug right at oil sump. So, with plastic valve off metal of drain plug, found that a 17mm wrench will fit over flat spots on the drain plug and easy enough remove. Note here that I found the drain plug was not really threaded into the oil sump all that much and thus probable reason for oil leak right at sump. So if you do not replace like I did, at least tight up plug into sump.