Ron Stultz

"Check Engine Light (CEL) - Detailed"

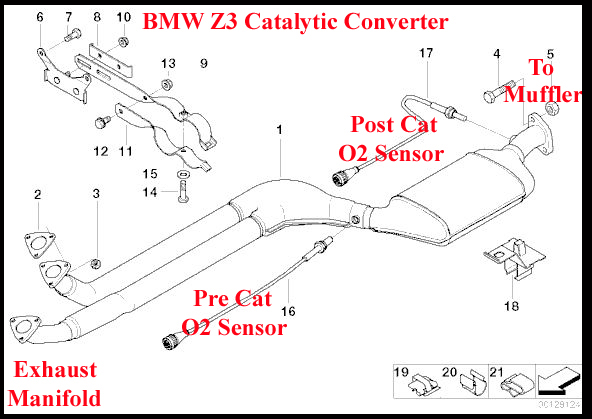

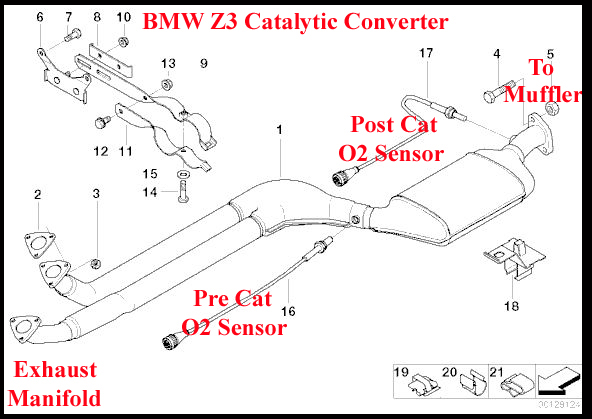

Summary: The Check Engine Light (CEL) on the BMW Z3 will come on for a variety of emissions related reasons. Because a Z3 has multiple engine management sensors interacting with an onboard computer, determining the root cause of the CEL can be a daunting task for a do-it-yourselfer (DIY), a BMW dealer or independent repair shop. And although a CEL for most owners usually translates into a failure of the oxygen sensor (O2) just before the catalytic converter, this may or may not be the problem.

Background:

My experience comes from owning a BMW Z3, Model year 1997, 2.8L, 50,000 miles and a model year 2000, X5, 4.4L, 140,000 miles.

The CEL will illuminate:

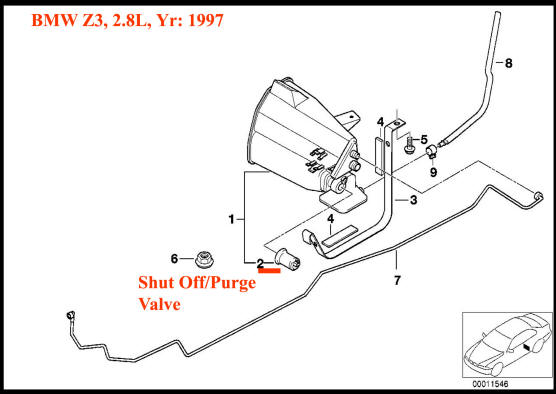

(1) if there is a problem with the car's fuel evaporative system (gas cap, fuel tank filler neck, fuel vapor charcoal canister, charcoal canister purge valve, or a fuel vapor leak somewhere). The idea of the evaporative system is to keep gasoline vapors from escaping the fuel system into the atmosphere.

(2) if the onboard computer, electronic control unit (ECU), detects a problem with emissions.

If the car is running fine with no symptoms other than the CEL, it has been my experience that this means either an fuel system vapor leak or there is a problem with the catalytic converter (CAT).

If the car is hard to start, stalls, runs rough or exhibits any other engine running poorly conditions, then the possibilities as to potential causes increases greatly and usually is not as simple as the pre Cat O2 sensor.

How a fuel injected car is suppose to work (its complicated):

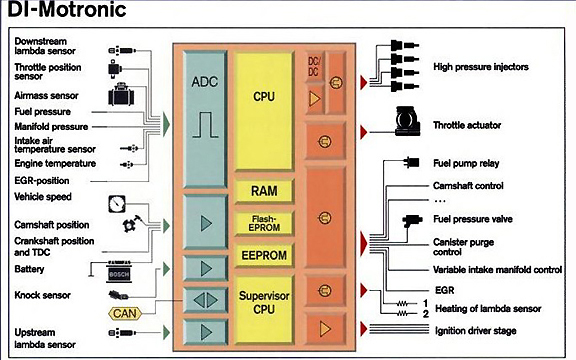

The heart of the engine management system is the ECU. This simple computer connects to various sensors and based on various conditions, changes the amount of fuel being injected into the cylinders and well as determining when the spark plugs are energized to get the maximum energy out of each cylinder's gasoline/air mixture.

Whenever the car is started, the ECU does a quick check of various engine management sensors. If a problem is found, it may be displayed on the dash console but definitely makes a note of the fault in a table it maintains inside itself known as diagnostic trouble codes (DTC's).

An ECU does not have a hard drive like found in personal computers but does have 2 distinct types of memory: regular memory that looses its stored information whenever power is removed from the ECU and programmable read-only memory (PROM) that holds its information even if the battery is removed from the car. The types of Prom memory data include car odometer and long term fuel trim, etc.

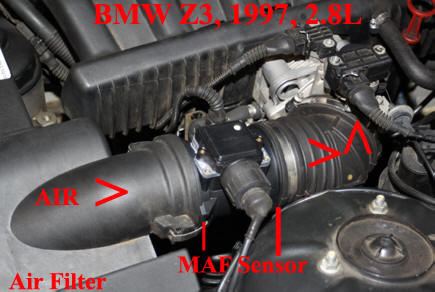

When a car is started from a dead cold state, the ignition key energizes the

starter that causes the engine crankshaft to rotate. The ignition key also

activates the fuel pump that sends fuel through the fuel filter to the fuel

pressure regulator (fuel pressure at the fuel injectors must be at a defined

pressure for the ECU control of fuel injector gasoline deliver to a cylinders to

be accurate.) As a cylinder goes down on

its fuel intake stroke, causing a vacuum and pulling in air from the intake

manifold, the ECU uses the coolant temperature to determine if it needs to

enrich the fuel/air mixture and based upon the temperature of the air entering

the intake manifold (intake air temperature sensor) and the mass of the air

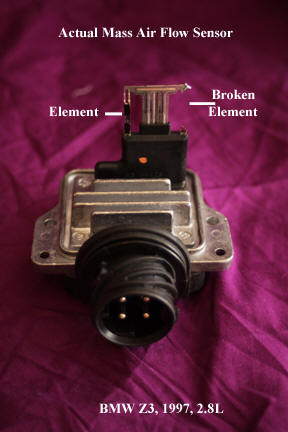

being pulled into the engine via the Mass Air Flow sensor (MAF). increases the

amount of time fuel injectors are open in the fuel intake stroke and also

adjusts spark plug timing for a start condition. As the oxygen sensors installed

just before and after the CAT do not function until they reach a temperature of

about 600 degrees, the ECU energizes an oxygen sensor heater control circuit that begins the

internal heating of the O2 sensors. This is done to reduce the time before the

O2 sensors can take an active role in regulating system fuel injection.

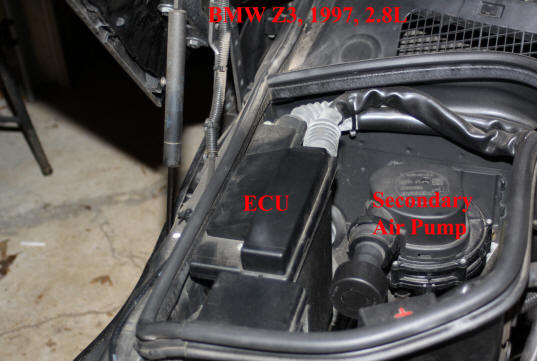

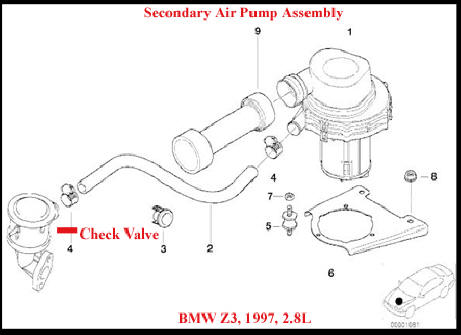

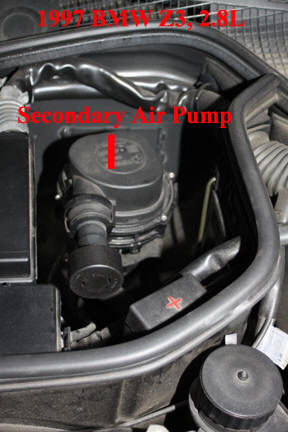

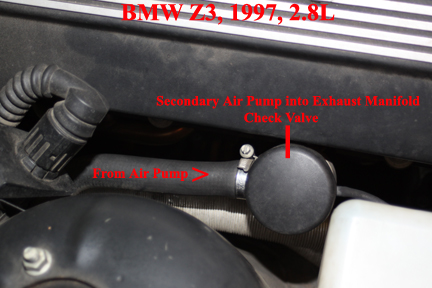

Because at start up the car runs rich (more fuel per volume of air) to help the car get started, the ECU starts the secondary air pump, which pumps outside air directly into the exhaust manifold. This is done to help the catalytic converter "burn" excess fuel in the exhaust. The air pump runs for a short period of time, perhaps based on coolant temperature or the stored ECU startup fuel map. (Map here refers to a stored program that more or less ignores various sensors.)

As coolant temperature rises, the ECU begins to adjust the fuel/air mixture entering the cylinders on each air intake stroke but initially based on the stored fuel map.

Once the O2 sensors begin to operate, the ECU uses the voltage coming from the pre Cat O2 sensor to adjust the time the fuel injector is open or dispensing its spray of gasoline. As the front O2 sensor begins to show a fuel rich condition, the ECU begins to lean out the fuel/air mixture and does so until the front O2 sensor begins to show a lean condition, where upon the ECU begins to enrich the mixture once again. The idea here is that the front O2 sensor and the ECU try to achieve a perfect 14 parts air to 1 part gasoline mixture all the time through any driving situation.

O2 sensors, once they reach their operating temperature, only produce voltage when there is a difference between the O2 content inside the exhaust piping and the atmosphere. If there is no difference between the O2 content inside the exhaust piping and the atmosphere, the front O2 sensor produces very little voltage. If a car is running rich, all oxygen pulled into a cylinder will be consumed and thus little or no oxygen is present in the exhaust. If a car is running lean, not all oxygen pulled into the cylinder is burned (not enough fuel) and thus excess oxygen is present in the outside stream and the pre Cat oxygen sensors reports a very low voltage.

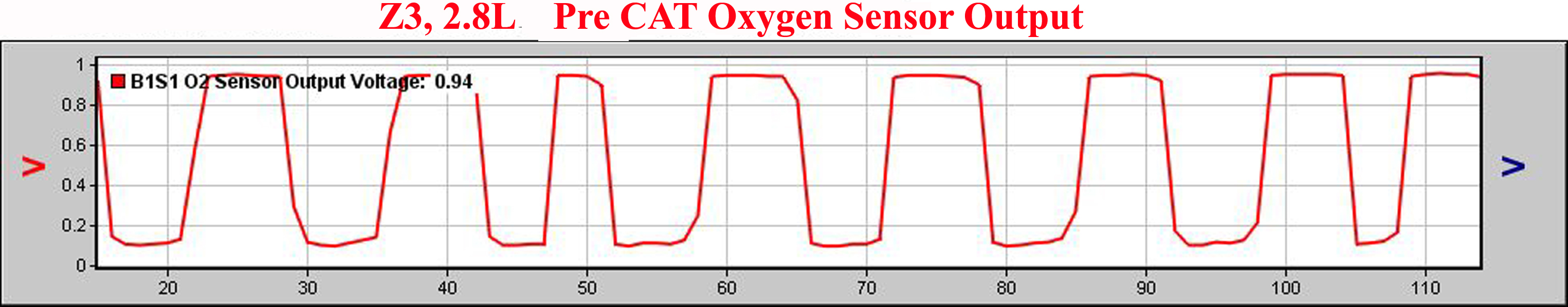

The image above shows the pre CAT oxygen sensor output from a Z3, 2.8L. High voltage indicates a fuel rich condition (limited oxygen in exhaust stream) while a low voltage indicates a fuel lean condition with excessive amounts of oxygen in the exhaust stream.

If the pre Cat O2 sensor is dead, meaning it is not producing any voltage at all for whatever reason to include a bad connector, the ECU will interpret this to mean that the car is running lean and try to enrich the fuel/air mixture. If this happens, the car can begin to smoke or the tailpipe get sooty from excess fuel and the catalytic converter can be damaged by it having too much fuel inside it that it has to "burned."

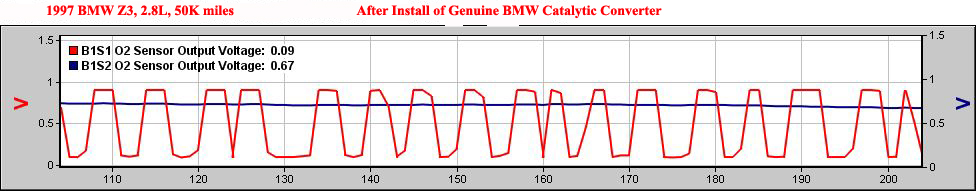

As the exhaust enters the catalytic converter, the special element in the converter burns off excess fuel and also eddies out too much oxygen. The function of the oxygen sensor post Cat is to monitor the efficiency of the CAT. The post CAT oxygen sensor when functioning properly with a fully functioning catalytic converter will have a constant voltage output that does not vary no matter the engine fuel rich or lean condition.

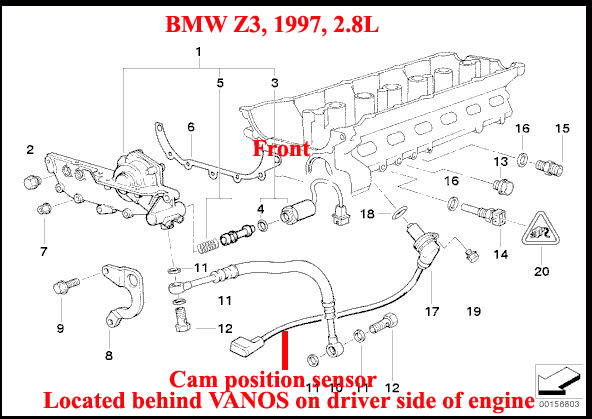

So once the car is at temperature, the ECU uses the O2 sensors, the MAF, the throttle body position sensor, the air intake temperature sensor (mounted up underneath the throttle body), the coolant temperature and the cam angle sensor to constantly adjust the fuel/air mixture and engine spark timing.

.jpg)

.jpg)

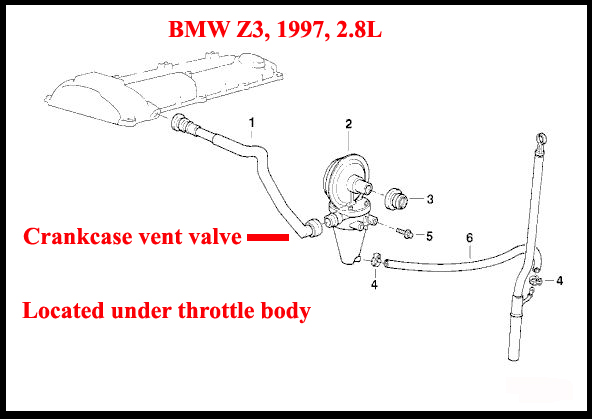

Beside the ECU and its sensors, there are various other components tied into the engine fuel management system. These items include the fuel vapor canister purge valve, engine crankcase ventilation valve (CVV) and ping or knock sensors. In the case of the charcoal canister, any vapors "stored" there are sucked into the intake manifold at various times when the ECU commands the purge valve to open. If with perfect rings on cylinders, there will always be some amount of exhaust gas blow by, meaning that there will some leakage of the fuel/air mixture after combustion into the crankcase. To recycle these fumes, the CVV routes them into the intake manifold to be mixed with the incoming air for subsequent "reburn."

As the car runs, the ECU monitor ping sensors that monitor the crank shaft. Should a cylinder start detonating fuel too soon and thus causing "ping", the ECU retards spark plug ignition.

As the car is driven overtime, it uses the voltage from the pre CAT oxygen sensor to develop what is known as the long term fuel trim (LTFT). This value, expressed as a percentage, is the amount of adjustment the ECU should use to fuel injection times as a baseline from its stored, or default injection times. The LTFT is a value unique to each car and represents variations in various components as they age. LTFT is stored in PROM but is adjusted by short term fuel trim (again, as determined by the pre CAT O2 sensor) over time.

Now in an attempt to make a check of the fuel management system easy for service technicians and those involved in verifying that a car is meeting current emissions standards in effect in the local jurisdiction, BMW cars are equipped with a special computer interface port known as OBCII or the onboard computer interface II.

What Can Go Wrong - CEL:

Obviously from the "normal operation" description above, a lot of different components are involved in fuel management and thus emissions and the dreaded CEL. Ok, so you have a CEL, what do you do? Most people just take the car to a shop and that is the end of it, but if you are so inclined to try to same some money and like doing things yourself, CEL is not beyond being diagnosised by an owner. But you have to have a special tool and that is what is known as a scanner, which is connected to the OBCII interface defined above.

There are 5 types of scanners in the market: (1) Very simply, reset devices, that allow an owner to reset the CEL and perhaps retrieve some stored DTC's. Beyond the OBCII interface and what can be examined using it, BMW cars also have other special to BMW DTC's that simple scanners will not recognize (2) A more sophisticated handheld scanner that that looks at OBCII data and perhaps can display some information in real time. Example of real time display is where you want to look at the voltages of the pre and post CAT O2 sensors. This type scanner is available for free use at most AutoZone retail parts stores but do not expect to borrow it and immediately make heads or tails out of what is displayed. (3) More sophisticated personal computer-based hardware and software. With this type of scanner and add-on software specific to BMW, an owner can see most DTC's and look at various engine management data in real time. For example, one can see MAF sensor readings, the intake manifold temperature reading, etc. etc. (4) Independent BMW repair shops scanners and (5) Dealer scanners, which are very expensive and can be used to read all DTC's as well as "code" various replacement components to a car.

Ok, so you get a scanner of some type. Obviously the first thing to look at is the pre and post CAT 02 sensor voltages. As described above, if the front sensor is not changing while the engine is running or is very sluggish in changing from rich to lean or lean to rich, it is probably defective and needs to be replaced. If the post CAT O2 sensor does not have a steady voltage, this may or may not mean you have a bad catalytic converter.

Things that can totally screw with the engine management system include: intake manifold leaks; exhaust leaks; vacuum leaks, a MAF that is misreporting intake air mass; a defective intake temperature sensor, etc. etc. A scanner that shows DTC's will help you identify issues that might be causing your CEL beyond it simply being the pre CAT O2 sensor or a bad CAT.